Fixed electrical sensors are an essential component in various industries, including manufacturing, automotive, and aerospace. These sensors play a crucial role in detecting changes in the environment and converting them into electrical signals for monitoring and control purposes. To ensure the reliability and performance of fixed electrical sensors, there are specific product standards that manufacturers must adhere to. In this article, we will explore the product standards for fixed electrical sensors and their importance in ensuring the quality and safety of these devices.

1. Accuracy: Fixed electrical sensors must be able to accurately detect changes in the environment and convert them into electrical signals with a high degree of precision. The accuracy of a sensor is typically expressed as a percentage of the full-scale output and is determined by factors such as resolution, linearity, and hysteresis.

2. Sensitivity: Sensitivity refers to the ability of a fixed electrical sensor to detect small changes in the environment and produce a corresponding electrical signal. Sensors with high sensitivity are able to detect subtle variations in temperature, pressure, or other parameters, making them ideal for applications where precision is critical.

3. Stability: Fixed electrical sensors must maintain their performance over time and under varying environmental conditions. Stability is a measure of how well a sensor retains its calibration and accuracy over extended periods of use, ensuring consistent and reliable operation.

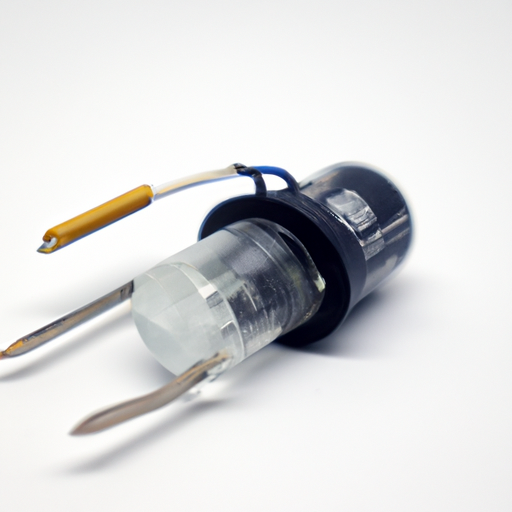

4. Durability: Fixed electrical sensors are often exposed to harsh operating conditions, such as high temperatures, humidity, and mechanical stress. To ensure their longevity and reliability, sensors must be designed to withstand these conditions without compromising their performance.

5. Compatibility: Fixed electrical sensors must be compatible with other electrical systems and devices to ensure seamless integration and communication. Compatibility standards define the electrical interfaces, communication protocols, and signal outputs that sensors must adhere to for interoperability with other equipment.

6. Safety: Fixed electrical sensors must meet safety standards to protect users and equipment from potential hazards, such as electrical shock, fire, or explosion. Safety standards specify the design, construction, and testing requirements that sensors must meet to ensure their safe operation in various environments.

7. Environmental protection: Fixed electrical sensors used in outdoor or hazardous environments must meet environmental protection standards to prevent damage from dust, moisture, chemicals, and other contaminants. These standards define the degree of protection provided by the sensor enclosure against ingress of solid particles and liquids.

In addition to these product standards, fixed electrical sensors may also be subject to industry-specific regulations and certifications, such as those for automotive, aerospace, or medical devices. Compliance with these regulations is essential for ensuring the quality, reliability, and safety of fixed electrical sensors in their intended applications.

Manufacturers of fixed electrical sensors must conduct rigorous testing and quality assurance processes to ensure that their products meet the required standards and specifications. This may involve calibration, performance testing, environmental testing, and certification by accredited testing laboratories. By adhering to product standards and regulations, manufacturers can demonstrate the quality and reliability of their fixed electrical sensors to customers and regulatory authorities.

In conclusion, product standards play a critical role in ensuring the quality, reliability, and safety of fixed electrical sensors. By meeting the requirements and specifications set forth by organizations such as the IEC and ANSI, manufacturers can produce sensors that deliver accurate, sensitive, stable, and durable performance in a wide range of applications. Compliance with product standards also helps to ensure compatibility, safety, and environmental protection, making fixed electrical sensors a trusted and essential component in modern industrial systems.